390 Build

390 Build

I just dropped my 390 motor off for a mild rebuild, RV cam, 4V intake and headers. I'm pretty pumped after talking to the gentleman who will be doing the work. He's got his own shop out in farm country and came with good recommendations locally.

He'll be tearing it down and will let me know what he finds next week. I supplied him with Comp Cam/Springs/Lifters/Timing kit, and Felpro gaskets. After magnaflux, he will do the machining of the block, crank and heads, replace bearings, pistons and valves.

He had a lot of cool FE stuff sitting around and a 390 with a cross ram 8V Holley setup that I wish I had snapped some pictures of.

Does anyone have a recommendation for what pistons to run? I found some Silvolite 1130 pistons that were around 9:1 compression ratio, which is where I'd like to end up. He was going to come up with a few options and let me know the cost of each.

Regards,

Corey

He'll be tearing it down and will let me know what he finds next week. I supplied him with Comp Cam/Springs/Lifters/Timing kit, and Felpro gaskets. After magnaflux, he will do the machining of the block, crank and heads, replace bearings, pistons and valves.

He had a lot of cool FE stuff sitting around and a 390 with a cross ram 8V Holley setup that I wish I had snapped some pictures of.

Does anyone have a recommendation for what pistons to run? I found some Silvolite 1130 pistons that were around 9:1 compression ratio, which is where I'd like to end up. He was going to come up with a few options and let me know the cost of each.

Regards,

Corey

1966 F250 LWB

Re: 390 Build

Ford made a similar dished piston that had a couple of ramps in it that swirled the air/fuel mixture. Unless that is a generic picture, the top of the piston looks too tall to be .030 below deck. Are you using C7AE-A, C8AE-H or D2TE-AA heads? There ports and chambers will give you good low to mid range torque.

https://m.summitracing.com/parts/uem-11 ... aQod-34F0Q

https://m.summitracing.com/parts/uem-11 ... aQod-34F0Q

Chris

Re: 390 Build

Thanks Chris,chris401 wrote:Ford made a similar dished piston that had a couple of ramps in it that swirled the air/fuel mixture. Unless that is a generic picture, the top of the piston looks too tall to be .030 below deck. Are you using C7AE-A, C8AE-H or D2TE-AA heads? There ports and chambers will give you good low to mid range torque.

https://m.summitracing.com/parts/uem-11 ... aQod-34F0Q

Not sure about the accuracy of the picture, but I calculated .032 below deck when I ran the numbers. I had planned to have the heads from my 66 352 reworked. Then I learned that the C8AE-H heads from the 390 would have a smaller chamber volume, so I'm going with them.

I have a Felpro gasket kit for the rebuild which uses the 8554PT head gasket. From what I've found, the compressed thickness of that gasket is around .051. I'm wondering if it would be worth it to switch to Felpro 1020 gaskets to get to .041 compressed thickness? Any thoughts on the durability of these two gaskets? Durability might be more important to me than squeezing out a little higher CR.

Regards,

Corey

1966 F250 LWB

Re: 390 Build

Personally I have not had any problems with the 1020 gaskets. It is ideal to have .030-.035 quench. An estimate on that 390 piston dish is a little over 19 cc so you will want to get it closer to the head than a flat top piston.

Chris

Re: 390 Build

Realize the compression ratio quoted for pistons is for a specific head volume, stroke and head gasket thickness. You really need to do the math to make sure you are really at the compression ratio you want.

http://hotrodworks.net/hotrodmath/engine.html

Good luck with the build!

SPark

http://hotrodworks.net/hotrodmath/engine.html

Good luck with the build!

SPark

1932 Ford 5 window coupe. 302/C4

1962 8V-390/C6 Unibody Short Bed Soon to be Big Window - The Lincoln that never was

2013 F150 Super Crew Eco Boost 4x4

2015 Ford Edge for the little lady, because she said so!

2007 Mustang GT, 4.6-3V/5 Speed. Only 8680 miles on the clock.

More toys, I need more toys!!!

1962 8V-390/C6 Unibody Short Bed Soon to be Big Window - The Lincoln that never was

2013 F150 Super Crew Eco Boost 4x4

2015 Ford Edge for the little lady, because she said so!

2007 Mustang GT, 4.6-3V/5 Speed. Only 8680 miles on the clock.

More toys, I need more toys!!!

Re: 390 Build

You are right. A couple of years ago when I had looked at those pistons, just a bore would have put my engine at 8.4? static compression. Ultimately I would have needed 68 cc heads block trimmed and a shim gasket to get 9.8 static compression.LM14 wrote:Realize the compression ratio quoted for pistons is for a specific head volume, stroke and head gasket thickness. You really need to do the math to make sure you are really at the compression ratio you want.

http://hotrodworks.net/hotrodmath/engine.html

Good luck with the build!

SPark

Correct mapping is important. I know a man that took his Edsel 361 to a builder that ended up installing 360 truck pistons on an engine that originally had 75 cc heads. Somehow with the same heads he was told his engine was 9.5:1.

Chris

Re: 390 Build

Thanks Steve -LM14 wrote:Realize the compression ratio quoted for pistons is for a specific head volume, stroke and head gasket thickness. You really need to do the math to make sure you are really at the compression ratio you want.

SPark

I had a different calculator that I used a while back, but need to run the numbers again for the c8ae-h heads and a few different pistons. I've seen chamber volumes ranging from 68cc to 76cc when looking for the info on the c8ae-h heads - does anyone have a reliable source for that info? I suppose the only way to know for sure is to have them cc'd.

I'm shooting for 9:1 CR with this build but the current geometry only gets me to 8.6:1, and that's assuming best case of 68cc heads. The other details are .030 over bore with .051 gasket height and Silvolite 1130 pistons .032 down the hole.

Regards,

Corey

1966 F250 LWB

Re: 390 Build

Look at decking the block to get a zero deck height if possible. .040 quench (top of piston to deck of head) is considered ideal for the majority of combinations. You won't be able to get there with a .051 thick gasket. Don't forget to look at different head gaskets to help numbers, too.

SPark

SPark

1932 Ford 5 window coupe. 302/C4

1962 8V-390/C6 Unibody Short Bed Soon to be Big Window - The Lincoln that never was

2013 F150 Super Crew Eco Boost 4x4

2015 Ford Edge for the little lady, because she said so!

2007 Mustang GT, 4.6-3V/5 Speed. Only 8680 miles on the clock.

More toys, I need more toys!!!

1962 8V-390/C6 Unibody Short Bed Soon to be Big Window - The Lincoln that never was

2013 F150 Super Crew Eco Boost 4x4

2015 Ford Edge for the little lady, because she said so!

2007 Mustang GT, 4.6-3V/5 Speed. Only 8680 miles on the clock.

More toys, I need more toys!!!

Re: 390 Build

I was probably overdized on your piston cc. I was off on the 361 piston. I called Federal Mogul tech line and got a couple of specs for 361 and 390 pistons.MN66 wrote:I just dropped my 390 motor off for a mild rebuild, RV cam, 4V intake and headers. I'm pretty pumped after talking to the gentleman who will be doing the work. He's got his own shop out in farm country and came with good recommendations locally.

He'll be tearing it down and will let me know what he finds next week. I supplied him with Comp Cam/Springs/Lifters/Timing kit, and Felpro gaskets. After magnaflux, he will do the machining of the block, crank and heads, replace bearings, pistons and valves.

He had a lot of cool FE stuff sitting around and a 390 with a cross ram 8V Holley setup that I wish I had snapped some pictures of.

Does anyone have a recommendation for what pistons to run? I found some Silvolite 1130 pistons that were around 9:1 compression ratio, which is where I'd like to end up. He was going to come up with a few options and let me know the cost of each.

Regards,

Corey

H994P has a 16.02 cc dish

381P has a 11.7 cc dish

Chris

Re: 390 Build

Hey Chris,

When I looked at the Felpro 1130 spec, I think it was exactly what you said, 19cc.

The Silvolite 1131 piston, which has an 8cc dish volume would put me around 9.2:1 CR with the Felpro 8554PT gaskets, 72cc heads (most likely), .030 over bore and pistons .032 down the hole - that's right where I'd like to be.

I'm anxiously waiting to hear from my builder about the condition of the 390. Might know more by the end of the week when I drop off the valve springs and some other parts from my 352. I blasted and painted a bunch of 352 parts back when I thought that was my rebuild goal. At least that work wasn't wasted.

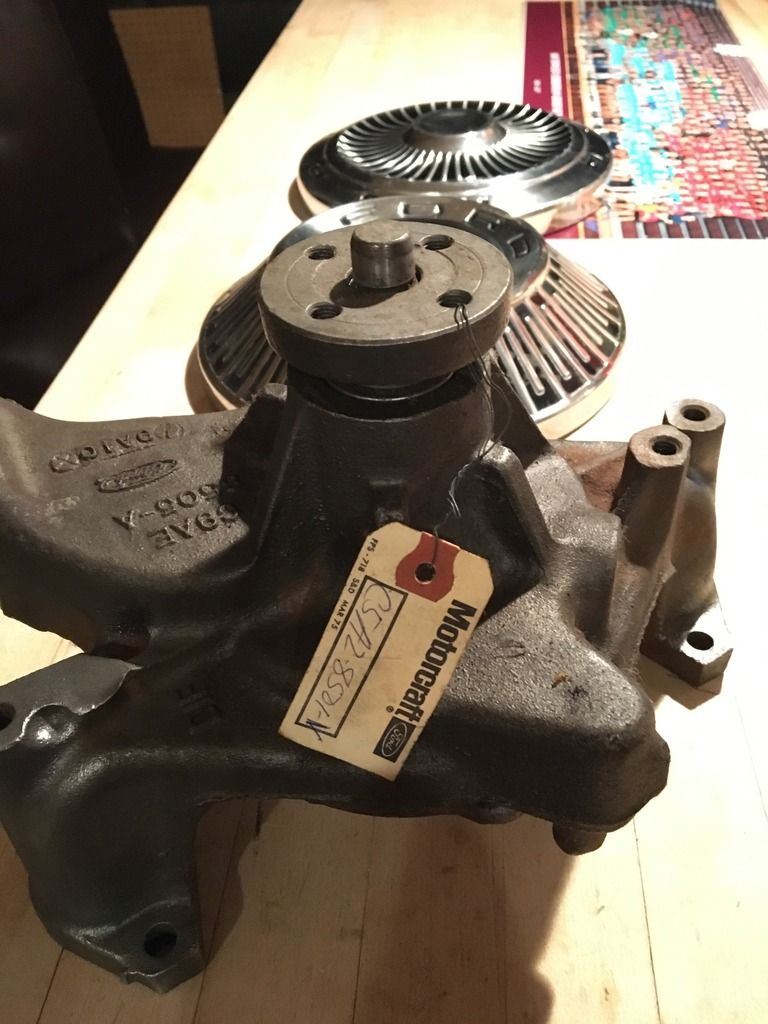

Should I be replacing my water pump, or just clean the old one up and slap it back on? I didn't have any overheating or noise issues with the old pump, so I was assuming it would go back on.

Thanks,

Corey

When I looked at the Felpro 1130 spec, I think it was exactly what you said, 19cc.

The Silvolite 1131 piston, which has an 8cc dish volume would put me around 9.2:1 CR with the Felpro 8554PT gaskets, 72cc heads (most likely), .030 over bore and pistons .032 down the hole - that's right where I'd like to be.

I'm anxiously waiting to hear from my builder about the condition of the 390. Might know more by the end of the week when I drop off the valve springs and some other parts from my 352. I blasted and painted a bunch of 352 parts back when I thought that was my rebuild goal. At least that work wasn't wasted.

Should I be replacing my water pump, or just clean the old one up and slap it back on? I didn't have any overheating or noise issues with the old pump, so I was assuming it would go back on.

Thanks,

Corey

1966 F250 LWB

Re: 390 Build

I don't remember ever buying a new FE water pump. Started my FE collection at 16 and the couple that leaked or were noisy were replaced from my spare parts shelf. Make sure your weep hole is not plugged. Otherwise you wont know if the bearing is water logged. The 69 and newer pump bearings are big and the pulley mount is close to it. The aftermarket pump I have appears to be a copy. Rebuild kits are $45 from Dead Nuts On.

Chris

-

orangeRcode

- Posts: 838

- Joined: August 2, 2014, 10:38 pm

- Location: Mustang, OK

Re: 390 Build

Good info. I just bought a new one when I went through my FE. I don't remember the exact price but I get a great discount at NAPA through my employer. Never thought about rebuilding it.

Re: 390 Build

Ok - here's a question for ya. I just bought a NOS water pump (and a car load of other old Ford stuff I don't need) at a local antique Ford parts store called Little Dearborn. They've been in business since 1952 and unfortunately they're shutting down their business and having an online auction. Any concern about using something that's been on the shelf for 50 years? It turns freely and only shows a little surface rust on the casting.orangeRcode wrote:Good info. I just bought a new one when I went through my FE. I don't remember the exact price but I get a great discount at NAPA through my employer. Never thought about rebuilding it.

The good news is that my 390 rebuild is done and hopefully things will go smoothly as I start getting it ready to drop back in my truck.

As I've mentioned, it's a pretty mild build with an RV cam (Comp 255DEH), 9:1 compression ratio, Holley Street Dominator intake, headers, and Holley 4180 carb. Can't wait to take the wrapper off this weekend!

Last edited by MN66 on March 31, 2017, 5:55 pm, edited 1 time in total.

1966 F250 LWB

Re: 390 Build

I have not run one shelved that long but you should be fine. The C9 pump I was running came from a 71 390 and had a matching date code. Quencidence or original pump I can't say. They last a long time. If you change your mind there would be a small window for someone needing your NOS waterpump for there March 1970 CJ/SCJ restoration. Pictures are what the kit and seal look like.

Chris

Re: 390 Build

Chris -I have not run one shelved that long but you should be fine. The C9 pump I was running came from a 71 390 and had a matching date code. Quencidence or original pump I can't say. They last a long time. If you change your mind there would be a small window for someone needing your NOS waterpump for there March 1970 CJ/SCJ restoration. Pictures are what the kit and seal look like.

Thanks for the thought on selling it for a restoration - I've got a bunch of other stuff to get ready for ebay, so I might throw it out there and see. I might just do a seal kit on my original 352 water pump since I went through the trouble of making it all sparkly.

The sender is from my 352, I don't recall what was on the 390 when I got it. Did they make a change to the senders between 66 and 69?Is your oil sender and sensor OEM for a factory gauge/light?

1966 F250 LWB

Re: 390 Build

The flat spade connector sensor is for a light, the big round sender is for a gauge. I didn't know if the OEM oil/amp bezel gauge used the light also.

Chris

Re: 390 Build

Both had wires connected, so I assume that's the case, having never witnessed the light coming on that I recall.chris401 wrote:The flat spade connector sensor is for a light, the big round sender is for a gauge. I didn't know if the OEM oil/amp bezel gauge used the light also.

1966 F250 LWB

Re: 390 Build

I made a little more progress this weekend on the 390.

I got my flywheel, clutch and bellhousing put together without too much trouble.

Then I hung the saginaw power steering pump and 3G alternator on the front to see what sort of issues I might have.

It looks like I'll need some longer spacers for the borgeson power steering bracket to make the pulley align with the crank pulley.

I'll also need to make the alternator tensioning bracket longer in order to accommodate the 3G alternator. I'll need to clock the back of the alternator and maybe grind one of the unused mounting ears on the back of the alternator in order to clear the head.

Has anyone done the 3G alternator upgrade on an FE?

Regards,

Corey

I got my flywheel, clutch and bellhousing put together without too much trouble.

Then I hung the saginaw power steering pump and 3G alternator on the front to see what sort of issues I might have.

It looks like I'll need some longer spacers for the borgeson power steering bracket to make the pulley align with the crank pulley.

I'll also need to make the alternator tensioning bracket longer in order to accommodate the 3G alternator. I'll need to clock the back of the alternator and maybe grind one of the unused mounting ears on the back of the alternator in order to clear the head.

Has anyone done the 3G alternator upgrade on an FE?

Regards,

Corey

Last edited by MN66 on March 31, 2017, 5:53 pm, edited 1 time in total.

1966 F250 LWB

Re: 390 Build

I also installed my PowerMaster Ultra torque starter this weekend. When I test fitted it, the solenoid interfered with the headers. I was able to clock the starter so the solenoid was at the 6 o'clock position roughly and my headers had almost 2" clearance.

Is there any issue with having the solenoid down low?

Is there any issue with having the solenoid down low?

Last edited by MN66 on March 31, 2017, 5:54 pm, edited 1 time in total.

1966 F250 LWB

[/quote]

[/quote]