??? for the TIg Welders

??? for the TIg Welders

I found someone that has a Tig welder that he wants to get rid of. He is a friend of desertjeeper. He has a Lincoln Precision Tig 185 with the cart, bottle, foot control and welding rods. He has everything.

What I need to know is this a beginner friendly Tig machine. I have only had a Tig in my hands about 2-3 times just to try it, so I don't really have any idea how to weld with it.

He wants a $1,000 for the complete setup. I think that it is probably a fair pric for what he has with it. I really need to know if it is user friendly. The pics look like it has been taken good care of.

I shouldn't spend that kind of money on a Tig welder right now but if it is a good deal, maybe I should go ahead and buy it.

Kevin

What I need to know is this a beginner friendly Tig machine. I have only had a Tig in my hands about 2-3 times just to try it, so I don't really have any idea how to weld with it.

He wants a $1,000 for the complete setup. I think that it is probably a fair pric for what he has with it. I really need to know if it is user friendly. The pics look like it has been taken good care of.

I shouldn't spend that kind of money on a Tig welder right now but if it is a good deal, maybe I should go ahead and buy it.

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

YES! I'd jump on that. Tig welding is definitely a challenge to begin with but that is a great machine and will last you awhile. The foot control makes tig welding much easier in the sense of not having to scratch start like the old days (what I had to do in school). You'll still have to learn how to achieve a proper weld, walking the cup, dipping the rod and all that but like anything else - practice, practice, practice! Plenty of goodies that go with it as well.

I have a Precision Tig 225 and I haven't found one single thing I don't like about it.

I have a Precision Tig 225 and I haven't found one single thing I don't like about it.

"If you don't want to stand behind our Troops, feel free to stand in front of them."

1964 Ford F100

1967 US Army M416

1964 Ford F100

1967 US Army M416

Kevin: That's a pretty decent deal, so if you don't buy it, they guy behind you probably will:)

Mine is the slightly older version (175), and I picked it up a few years back, it was about two or three years old, but the tig portion had NEVER been used, and he claims he only ever burned three stick rods, just to try it out when he first brought it home:) I believe that was about 2005, and I gave him $1400.00 for it, but it was at least an hour drive each way to go get it. (he started out @ $1500.00, but gave me a break to help offset the drive)

If you have done any oxy-acetylene welding, you will likely catch on to tig quickly, as the mechanics are very similar, just a different heat source to form the puddle......

HTH

James

Mine is the slightly older version (175), and I picked it up a few years back, it was about two or three years old, but the tig portion had NEVER been used, and he claims he only ever burned three stick rods, just to try it out when he first brought it home:) I believe that was about 2005, and I gave him $1400.00 for it, but it was at least an hour drive each way to go get it. (he started out @ $1500.00, but gave me a break to help offset the drive)

If you have done any oxy-acetylene welding, you will likely catch on to tig quickly, as the mechanics are very similar, just a different heat source to form the puddle......

HTH

James

- 66fordtrucknut

- Posts: 1289

- Joined: July 11, 2006, 11:48 pm

- Location: Eastern Shore - MD

I'm more of a Miller guy, not that familar with that welder is it DC only? If it's AC/DC and 185 amps you won't be doing much in the way of Alum. But sounds like a pretty good deal for everything. Tig welding is prob. one of the easiest welding processes when you get the hang of it, Good luck, any questions post up.

Charlie

Charlie

62' SWB uni 223

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

It's comparable to Miller's Syncrowave 180SD. I know a few guys at the airport who have used both the Lincoln PT185 and Miller's 180SD to build their RV kit planes. Plenty of aluminum welding depending on how you build it and what model.

"If you don't want to stand behind our Troops, feel free to stand in front of them."

1964 Ford F100

1967 US Army M416

1964 Ford F100

1967 US Army M416

- 66fordtrucknut

- Posts: 1289

- Joined: July 11, 2006, 11:48 pm

- Location: Eastern Shore - MD

So it's a squarewave machine? Still don't think it will do very heavy alum, for very long. I use a synchrowave 300 at work and have a dynasty 200 for portable stuff, works great on light stuff, but I don't do a whole lot of light stuff. I bring a bottle of helium to help.

Charlie

Charlie

62' SWB uni 223

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

Yes, it's a squarewave AC/DC, and why would you expect a 185A machine to do what a 300 Synchrowave or 350 Dynasty does in the first place??

Any of the 180-200 machines are big enough for 80% of the jobs that the average hobbyist will do, and without the considerable investment required for the two heavyweights mentioned above..........the tradeoff between capacity (amperage rating) and duty cycle of the smaller machines vs the heavyweights is why the smaller ones are 1/3-1/2 the cost........

James

Any of the 180-200 machines are big enough for 80% of the jobs that the average hobbyist will do, and without the considerable investment required for the two heavyweights mentioned above..........the tradeoff between capacity (amperage rating) and duty cycle of the smaller machines vs the heavyweights is why the smaller ones are 1/3-1/2 the cost........

James

- 66fordtrucknut

- Posts: 1289

- Joined: July 11, 2006, 11:48 pm

- Location: Eastern Shore - MD

You may wanna reread what I said, I never expected it to do what a 300 amp machine would do, and I have a 200 amp and it won't do what a 300 amp machine will. I didn't know if it was ac or not, wasn't putting any machine down, I said it was a good deal. Sorry you took it that way.

62' SWB uni 223

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

It's all good fellas! Yea, kit plane aluminum is definitely on the lighter side but bottom line is if you needed something bigger than a 185 amp TIG to do anything on our trucks... I'd like to know what the heck you're trying to do!

"If you don't want to stand behind our Troops, feel free to stand in front of them."

1964 Ford F100

1967 US Army M416

1964 Ford F100

1967 US Army M416

OK, new rule....I'm not allowed to respond to any posts unless it's been less than 30 minutes since my last cofee:):)

'nuff said

James

'nuff said

James

66fordtrucknut wrote:You may wanna reread what I said, I never expected it to do what a 300 amp machine would do, and I have a 200 amp and it won't do what a 300 amp machine will. I didn't know if it was ac or not, wasn't putting any machine down, I said it was a good deal. Sorry you took it that way.

I think that I will try and go look at it on Saturday. I have a neighbor that is a retired welder and he said that he would go and try it out for me. He has a Tig but I'm not sure what he has.

I would probably want it most to do aluminum welding. I would gues that the thickest piece that I would be welding would be 1/8" and maybe on occasion 3/16".

Thanks for all the comments.

I will let you know if I get it.

Kevin

I would probably want it most to do aluminum welding. I would gues that the thickest piece that I would be welding would be 1/8" and maybe on occasion 3/16".

Thanks for all the comments.

I will let you know if I get it.

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

- 66fordtrucknut

- Posts: 1289

- Joined: July 11, 2006, 11:48 pm

- Location: Eastern Shore - MD

Well, I bought this welder today. It appears to be in great condition. My neighbor, the welder, used it and said that it worked fine so I bought it. I was even able to make a decent looking bead on a piece of scrap metal.

Now all I have to do is go out and do a bunch of practicing and figure out how to make it work.

It came with the torch, foot pedal, bottle, a couple of tubes of rod, cart and several different types of tungsten tips.

This should be a fun learning experience.

Kevin

Now all I have to do is go out and do a bunch of practicing and figure out how to make it work.

It came with the torch, foot pedal, bottle, a couple of tubes of rod, cart and several different types of tungsten tips.

This should be a fun learning experience.

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

Nice looking unit there Kevin, I just got a precision Tig 225 in January, that only had about 10 hours on it. It is basically the same machine as what you have, just a little MORE POWER. If you are looking for some training videos, Lincoln has a bunch on youtube using the 185.

Dean

Dean

61 Mercury SWB Uni - Project

62 Mercury SWB BBW - Race truck

63 Ford SWB Uni - Daily driver (Jinx)

63 Ford SWB Uni - Parts truck

62 Mercury SWB BBW - Race truck

63 Ford SWB Uni - Daily driver (Jinx)

63 Ford SWB Uni - Parts truck

I need all the training videos that I can watch or read as I have no idea what I am doing but I will figure it out enough to be able to do what I need to.61 Merc wrote:Nice looking unit there Kevin, I just got a precision Tig 225 in January, that only had about 10 hours on it. It is basically the same machine as what you have, just a little MORE POWER. If you are looking for some training videos, Lincoln has a bunch on youtube using the 185.

Dean

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

- 66fordtrucknut

- Posts: 1289

- Joined: July 11, 2006, 11:48 pm

- Location: Eastern Shore - MD

Just start welding, you'll pick it up in no time. Get some tips from your nieghbor. Don't scimp on gas coverage, use the rgiht size tungsten to what your welding, you'll be an expert in no time. Congrats.

Charlie

Charlie

62' SWB uni 223

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

66' F-100 Short/wide 352

78' F-350 dually dumpbed 400

12' F-150 5.0 3:73 LS

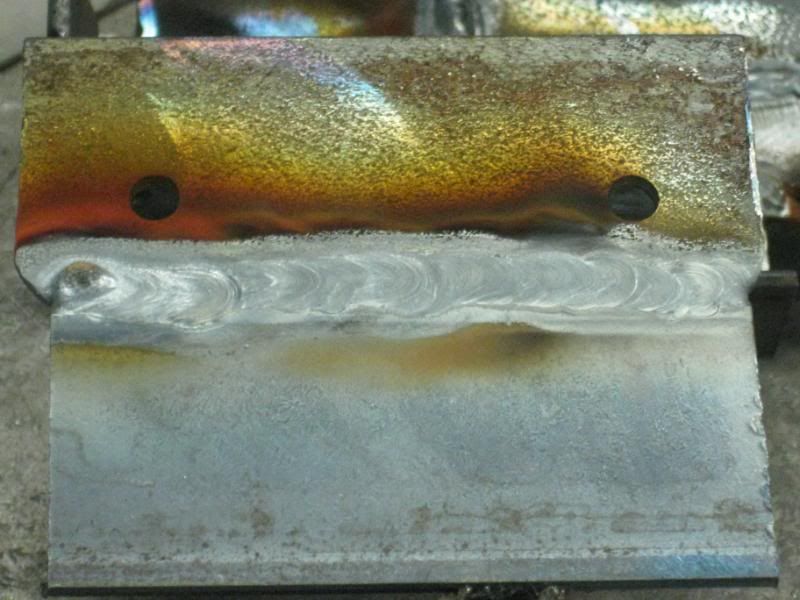

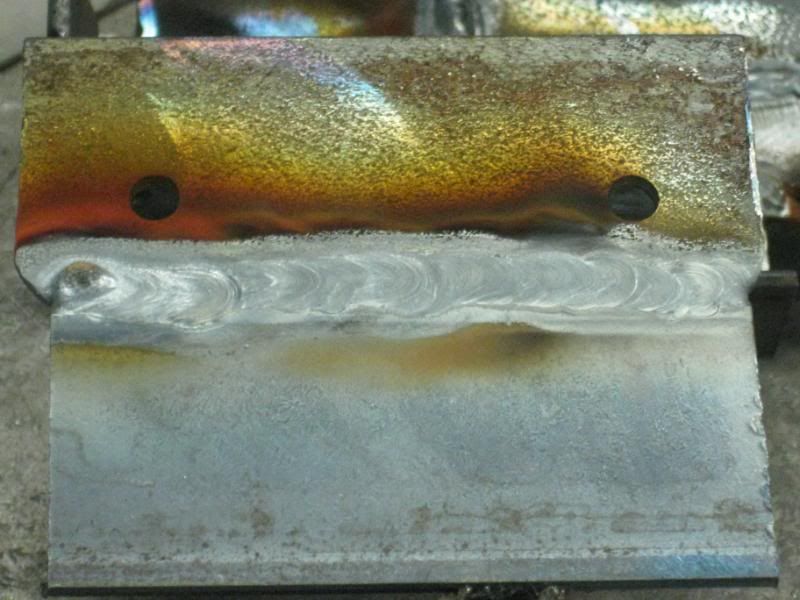

I played with the TIG today for a little while.

Here is what I ended up with. I just started picking up scrap pieces, grinding them a little bit and trying to weld them up.

This was all 1/8" material.

I tried some aluminum welding and thin sheet metal but I won't show those pics yet. I had a terrible time with the thin metal.

I had a few good welds on the aluminum but then I would just start screwing up after that.

I just need a lot more time with the machine.

Kevin

Here is what I ended up with. I just started picking up scrap pieces, grinding them a little bit and trying to weld them up.

This was all 1/8" material.

I tried some aluminum welding and thin sheet metal but I won't show those pics yet. I had a terrible time with the thin metal.

I had a few good welds on the aluminum but then I would just start screwing up after that.

I just need a lot more time with the machine.

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

Looks like you need to put a little less heat into the weld, but a great start. Think also a faster travel speed with a lighter touch with the filler metal..... I am still learning myself, so correct me if I'm wrong.....

-1966 Ford F100, 352, 4 speed, smoke grey, mustang buckets

-2003 Ford Ranger XL, 3.0, 5 speed

-1989 Ford F250, 460, highboy, 4x4

-2003 Ford Ranger XL, 3.0, 5 speed

-1989 Ford F250, 460, highboy, 4x4

I think that you are correct. I had a couple of spots that I welded both sides of the joint and it burned completely through the weld on the other side.f100matt wrote:Looks like you need to put a little less heat into the weld, but a great start. Think also a faster travel speed with a lighter touch with the filler metal..... I am still learning myself, so correct me if I'm wrong.....

I will keep practicing.

Kevin

kstones63

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel

_______________________________________

63 F100

29 Ford Sedan Delivery

99 F250 PSD, 4x4, CC

95 F350 Flatbed Dually Diesel