Page 1 of 2

Straight Axle - Front Sway Bar - Another Option

Posted: September 24, 2009, 9:35 pm

by Max

Here is how I did the front sway bar on my '64 F100 Straight Axle truck.

**I will not know for awhile how this will work as I'm a ways away from driving my truck.**

After seeing the sway bars that Don Miller purchased for his '65, I thought this was what I was looking for. This is also how the sway bar is installed on my Jeep Wrangler.

I have everything needed to do Skip's Ranger version, but since installing the rack & pinion, wasn't sure I would have the room on the axle for the sway bar as well.

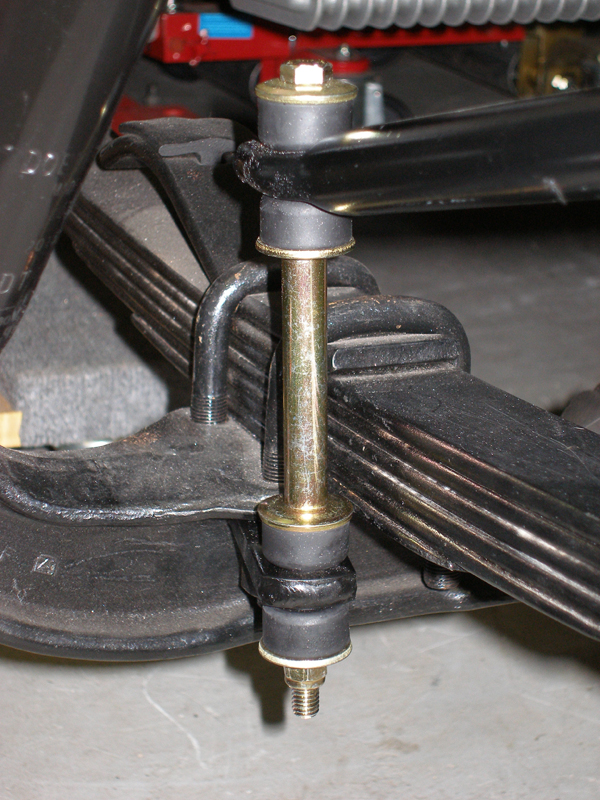

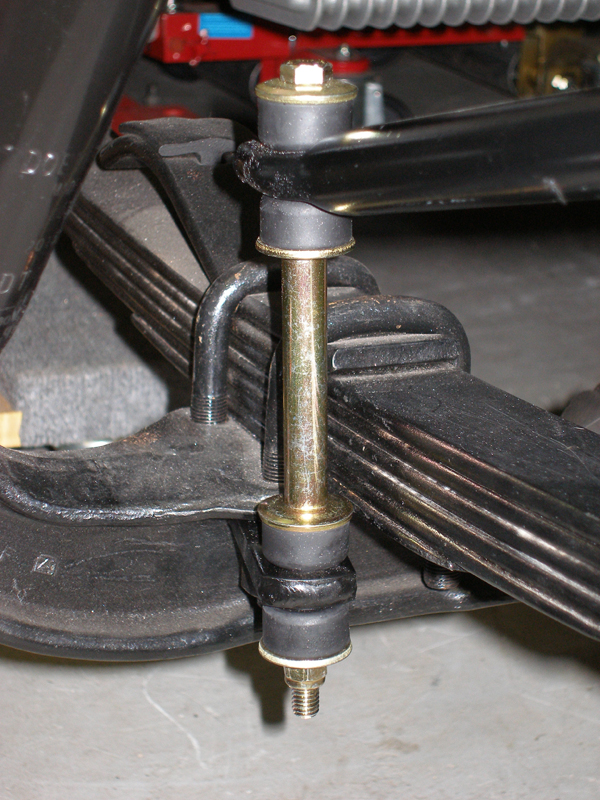

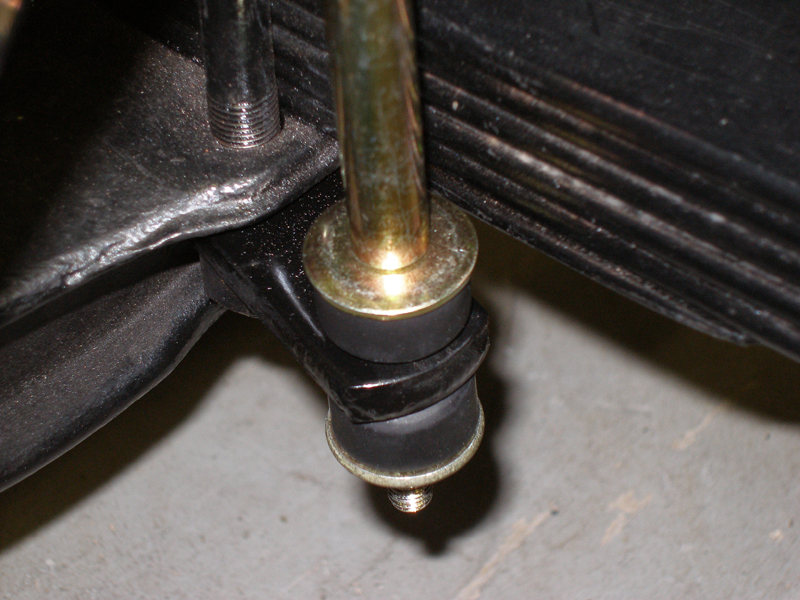

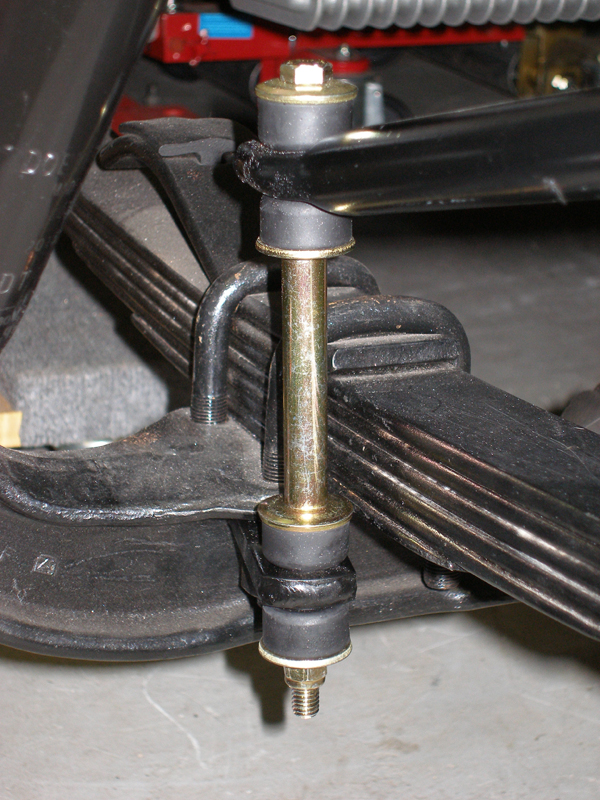

Sway bar is from a 67-72 F100 ($139-Summit Racing/Aadco), but fits our frame width perfectly. I bought 4 spring shackle links from Northern Tool to attach the drop links to ($8 total). I tig welded 2 together on each side to give me a 3/8" pad and painted them with chassis paint.

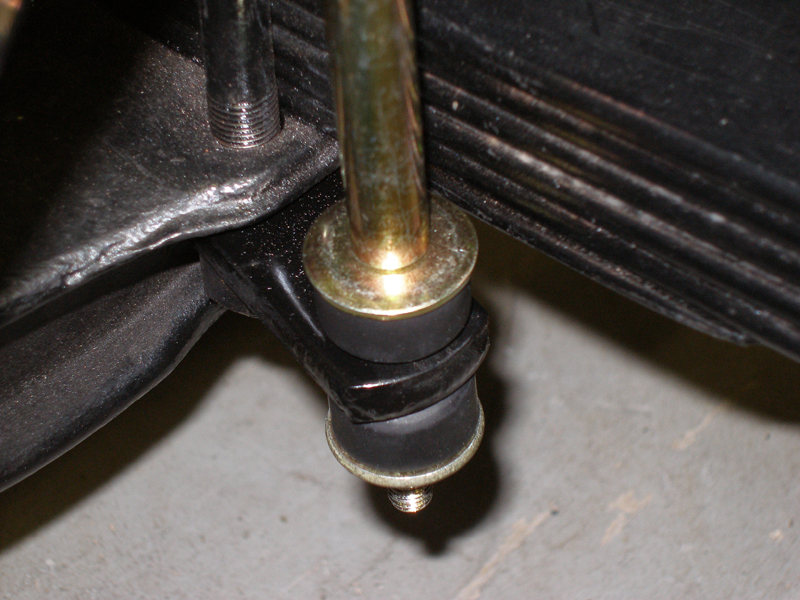

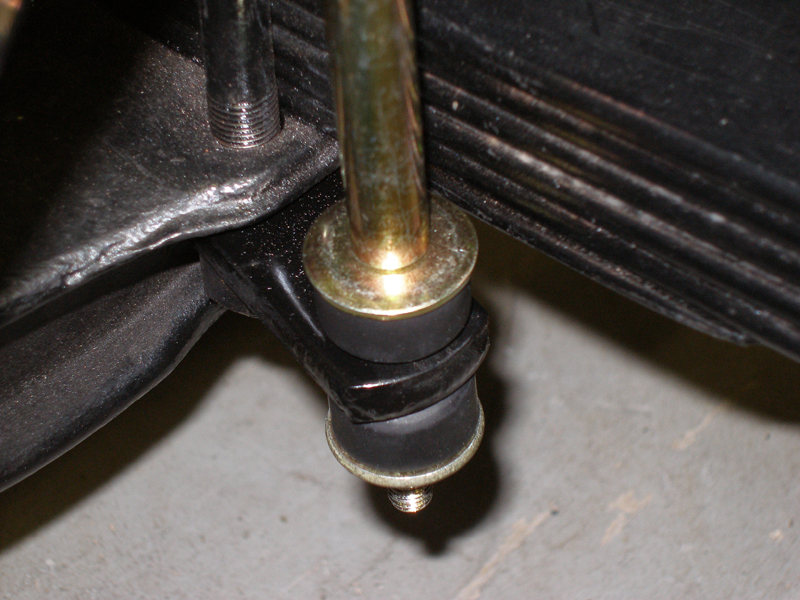

One end attaches to the bottom spring u-bolt and the other end holds the droplink. In order to do this correctly and keep the end of the sway bar level with the lower droplink attachment, I had to buy longer links. I went with 8.5", Grade 5 zinc plated bolts and longer spacer but used the original polyurethane bushings.

Here is completed installation:

Posted: September 24, 2009, 9:46 pm

by Gritsngumbo

Max: Looks good. Should work. What R&P did you use. The one from No Limit?

Posted: September 24, 2009, 10:17 pm

by Max

Here are the individual parts that I used:

Pads for drop links (I bought 2 sets, stacked 2 of them and welded together so it becomes 3/8" thick:

http://www.northerntool.com/webapp/wcs/ ... uct%20Page

Sway Bar (Addco 113):

http://www.summitracing.com/parts/ACO-113/

Longer Droplink Bolts:

http://www.fastenal.com/web/products/de ... 130&ucst=t

Posted: September 25, 2009, 8:49 am

by jwh f-100

VERY NICE Max!!

How long were the links that came with the sway bar kit??

Posted: September 25, 2009, 11:38 am

by charliemccraney

That is great! Something to add to the to do list.

Posted: September 25, 2009, 8:51 pm

by loosrp

Great info

NICE TRUCK UNDERCARRAGE!!!!!

Posted: September 25, 2009, 9:27 pm

by Max

Jason, links that came with the Addco kit were only 6" long. I needed mine 8.5".

Now those may work if you can figure out a different way to raise the attachment point for the bottom of the droplink. I just didn't find a good way and wanted to offset them away from the springs without interference.

Posted: September 25, 2009, 11:55 pm

by ezernut9mm

you got good welding skill stuff. lol. seriously. good. weld.

Posted: September 26, 2009, 11:47 am

by ICEMAN6166

that looks great Max.

i like the idea of the thicker drop shackles. i was going to weld bars between the 2 to beef them up as i have seen a large amount of bent ones on the trucks i parted out but now i might just make them thicker like yours.

Posted: September 29, 2009, 6:34 pm

by 64Ranger

Ok Max...quit scooting around the question:

Max: Looks good. Should work. What R&P did you use. The one from No Limit?

Is that R&P from No Limit?

Thanks

Posted: September 29, 2009, 7:00 pm

by Max

Oh man I'm sorry. I kept reading that and thought you were asking about where the sway bar came from! I'm a doofus!

Yes, rack & pinion is from No Limit. I 'acquired' it from another member who was going to use it but found a twin I-beam truck to work on instead.

Posted: September 29, 2009, 8:14 pm

by Greg D

Looks like the drop links that come with it would work with my monos.

Posted: September 29, 2009, 8:43 pm

by deviant1

Nice job Max!

Posted: September 29, 2009, 10:23 pm

by Gritsngumbo

Gritsngumbo wrote:Max: Looks good. Should work. What R&P did you use. The one from No Limit?

Glad to see someone who use the No Limit R&P. If you don't mind, what's your impression so far. Easy to install? Any problems? How'd you handle the steering shaft? Does it work well for you? Thanks.

Posted: September 29, 2009, 11:28 pm

by Max

I'm about 65% through the install of the rack & pinion and will be awhile before I finish. I have the actual rack loosely installed on the axle and attached to the wheels. I will have to modify my steering column (auto) but so far don't see any issues other than installing some sort of bearing on the end of the column where it would normally rest on the steering box.

It won't be complete until I get the cab back from paint and actually install the column back in the cab and finish the steering linkage.

It's a pretty solid unit (Ford part) and the machined aluminum brackets seem pretty stout as well. I'm running a Mustang power steering pump on the 351W and just trying to keep everything Ford and simple.

Posted: December 9, 2009, 12:49 pm

by Gary Seymour

This is a great sway bar application. I am about to pull out the credit card! Just curious as to how it might work on a lowered truck. Just keep the standard length link bolts? My spring eyes are reversed and then I have a dropped axle, but the reversed eyes would be the only thing that brings the axle closer to the frame. Seems like I'd be alright with this.

Great post!

Posted: December 11, 2009, 9:36 pm

by Max

Yes, the stock links would either work or you would have to go with even shorter ones. Best to just get the kit and then you'll be able to loosely fab it up to see what you'll need for droplink length.

Posted: December 12, 2009, 8:44 am

by Gary Seymour

It would probably be best to have the truck sitting at ride-height before locating the sway bar mounts to the frame....I guess I am a long way from doing this since I have a bare frame. Might go ahead and get the parts, though.

Posted: December 13, 2009, 7:11 pm

by jwh f-100

I said it once I'll say it again,,, VERY NICE Max!!

One thought, maybe a bad one..

Next time you have your welder out put a couple "nubs" on either side of your shackles so they won't break loose your u-bolt nuts and move side to side...

Posted: December 14, 2009, 12:20 pm

by LM14

Not to be negative, but I think you have built something that compromises the entire front end of the pickup.

When you twist the roll bar in a corner or over a bump, you will pul all the load on a single, from what I see unsupported, leg of the axle U-bolt. What is to keep the plate you fabricated, and hooked the sway bar link to, from twisting downward and bending or breaking the u-bolt? You doubled the plate so it wouldn't bend, what's to keep the u-bolt from bending?

There is a tremendous amount of force being applied to the lower mount and you are planning on using a single nut to hold everything in place? Not too sure that's a good idea. On a car sway bar, the lower link bolts through the lower control arm so it keeps everything in compression except the sway bar itself, which is in tension from the torsional loading. You are putting your lower mount in tension, not compression as it needs to be.

I could be all wrong, and for your sake I hope I am, but I wouldn't do this to anything I planned to drive.

JMO,

SPark