Rusty 63 F100 + 04 CV PI

-

Gritsngumbo

- Posts: 5441

- Joined: August 4, 2007, 4:15 pm

- Location: Monroe, Louisiana

I'd say drill new holes and move it forward like you planned. Think you'd always regret it if you don't.

If you understand what you’re doing, you’re not learning anything.

LITTLE RED: 64 F100 Short Style

BIG RED: 62 F100 Long Uni

BIG “UN": 63 F250 Long Flare

BBW RED: 61 F100 CC BBW Long Uni

CRIMSON CREW: 63 F100 "Stageway" Long Flare Crew Cab

"RANGER": 66 F100 CC Long Flatbed

"AVA" 1963 Avion T-20 Travel Trailer

“Lucille” 1955 New Moon 44’ Travel Trailer

LITTLE RED: 64 F100 Short Style

BIG RED: 62 F100 Long Uni

BIG “UN": 63 F250 Long Flare

BBW RED: 61 F100 CC BBW Long Uni

CRIMSON CREW: 63 F100 "Stageway" Long Flare Crew Cab

"RANGER": 66 F100 CC Long Flatbed

"AVA" 1963 Avion T-20 Travel Trailer

“Lucille” 1955 New Moon 44’ Travel Trailer

- Roger Carter

- Posts: 730

- Joined: July 5, 2008, 7:11 pm

- Location: Corbett, Oregon

Paul,

With the caliber of your project, not to mention the quality of work you have performed, I would not start cutting corners now. Pretty sure that if you did slot the holes, you would be back re-doing them before the truck hits the road.

My father always told me that "if you have to ask the question, you already know the answer"

I vote you plug the holes and do the job right.

Roger Carter

With the caliber of your project, not to mention the quality of work you have performed, I would not start cutting corners now. Pretty sure that if you did slot the holes, you would be back re-doing them before the truck hits the road.

My father always told me that "if you have to ask the question, you already know the answer"

I vote you plug the holes and do the job right.

Roger Carter

- unibody madness

- Posts: 2140

- Joined: December 4, 2008, 4:33 pm

- Location: Paradise,CALIFORNIA 95969

My opinion may not count for anyone but me,and in the end making yourself happy is all that matters, however you already learned how to do it, Right? So mock up one fender, bolt on one wheel and rim, lower it down to the expected ride height, and see if you can live with it. If not, move the cv forward until you are happy. Recalculate the holes fill the bad and go from there.

Concidering the amount of work you are doing,you should make sure you have no regrets when finished.

Just sayin

Concidering the amount of work you are doing,you should make sure you have no regrets when finished.

Just sayin

Turk build thread at:

viewtopic.php?f=32&t=18944

It does not matter what you think, it only matters what you do about it!

viewtopic.php?f=32&t=18944

It does not matter what you think, it only matters what you do about it!

We move forward, we move back....

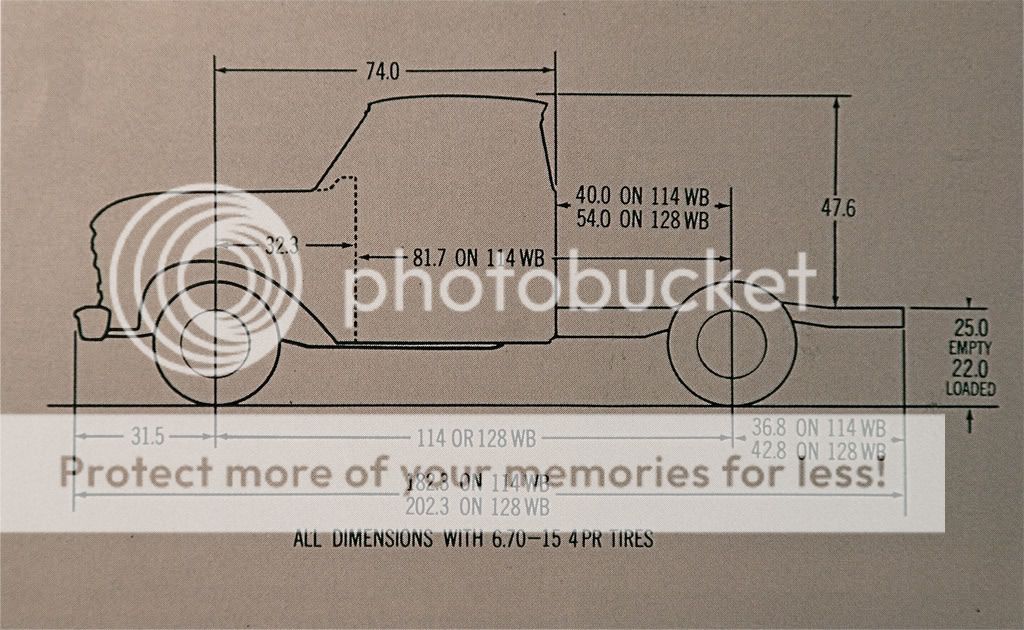

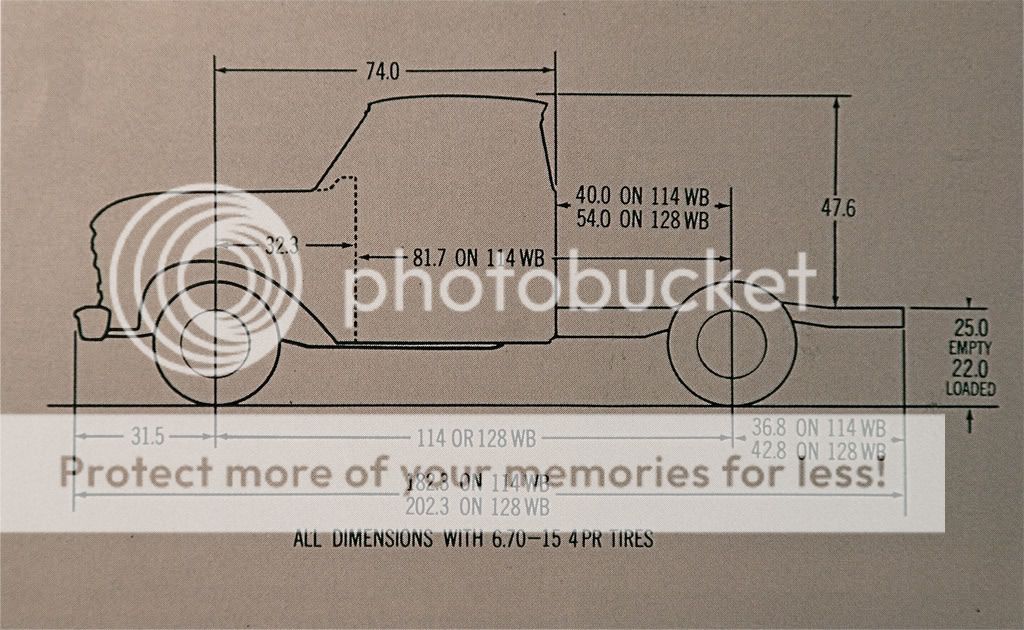

Ok, so first thing yesterday I did a bunch of research & reading about the wheelbases on our trucks (I had the dimensions someplace, but couldn’t find them). Here’s the magic Ford diagram (it was labeled as being from 1964 but applying to 61-64 model years):

(NOTE: I *should* have made a note of who posted this diagram on this site originally & gave them credit here. My thanks to you for your help!)

I’m dealing with a 63 shorty, so 114” is the stock wheelbase. After some searching, I come to find the 2004 CV donor had a 114.6” wheelbase. So, by moving the front axle centerline a fat ½” forward from stock, I could put the CV rear end in the “stock” (for ’61-64) location & run the complete CV drivetrain, including the driveshaft without alteration.

I did some measuring on the truck & find that (due to the previously discussed measurement issues) that the currently installed wheelbase on my truck is 114.5”. Wow. I’m there!

But then I think to my other reading. On the 65’s & up, the wheelbase is 115”, the inch gained by pushing the front axle forward - which means I’m currently halfway between “stock” for ‘61-‘64 & “stock” for ‘65 & up.

Most of the guys I’ve read about move the axle CL forward by ¾” to 1 ½” – on 65’s & up… that’s why the guys building the ’62 Unibody LSR pushed theirs forward 2 ½” – they went with the “normal” 1 ½” in front of the 65’s (& up) already 1” forward dimension.

I now realize that I was actually aiming for ¾” in front of the ‘65 & up measurement which means I now know I want 1 ¾” in front of 61-64 “stock” – or 1 ¼” further forward than I am right now. Are we having fun yet?

Now I knew the engine & transmission slid into position just fine with the CV suspension in place where it sits – but what would happen when I slid everything forward? Measuring the engine sitting on the floor, and then the frame, it sure looked like the AC compressor clutch would interfere with the front crossmember framerail brace. So I went ahead & dropped it in to be sure.

I’ve got about ¾” clearance as it sits. Moving the suspension (and the engine bolted to it) 1 ¼” forward puts me ½” into the brace. A half inch notch wouldn’t leave adequate space for movement & belt installation (who wants to pull the engine to replace the serpentine belt?) so I added another ¾” to give me a little bit of space for that. I marked out my cutlines & plan to use a section of scrap CV framerail (with its radius edge) to box the notch.

Now, moving the axle & engine forward gets the wheels where I want them in the wheel wells – but it also pulls my driveshaft 1 ¼” out of the transmission tailshaft housing. D’oh!

So now I’m thinking I’ll have to revisit my work on the rear suspension. Drilling the mono’s to move the axle forward doesn’t sound like the answer I’m willing to risk my own life upon, never mind those wife & (soon to be born) son. (No offense to the ’62 Unibody LSR guys – I’m building this to be a fun truck to drive, on the street, with stuff in the bed on occasion – I am a home builder after all – and I do like to turn corners quick & give her a little gas once in a while. I can’t even imagine what snapping a monoleaf would do on the road, in traffic.)

So I’m thinking of moving the forward leaf spring brackets 1 1/8”* forward on the frame, drilling new holes and attaching them with something other than grade 8 bolts**. Looking at the rear spring hangers, I think they’ll be fine where they are – they’ll just arc a little further forward. Or does anyone think that I should move them too?

Moving my rear axle centerline forward – has that got anyone else worried yet? I hate all the extra space in the fenders, so I want to section them 3” in the middle to tighten them up visually. This just means that instead of getting a donor step to cut slices out of to extend my steps (my former plan), I can just trim up my fenders. It’s always easier to make things smaller…

Now as to whether or not I can leave my existing C-notch alone… I’ll let you know. I guess if I need to revisit it, I’ll just have to do that!

Thoughts?

*Why 1 1/8 vs 1 ¼? The CV wheelbase is 114.6. I’m currently 114.5. The tenth is “close enough” to 1/8 for conversational purposes. And frankly, I’d rather hang the yoke .025 further out of the tailshaft housing than .1” too far in – I think in too deep could cause more problems, right?

**I read a huge metallurgical tirade on Fordification about what bolts should and shouldn’t be used to attach suspension pieces, and it convinced me that grade 8 isn’t the answer here – I’ll see if I can find the link.

(NOTE: I *should* have made a note of who posted this diagram on this site originally & gave them credit here. My thanks to you for your help!)

I’m dealing with a 63 shorty, so 114” is the stock wheelbase. After some searching, I come to find the 2004 CV donor had a 114.6” wheelbase. So, by moving the front axle centerline a fat ½” forward from stock, I could put the CV rear end in the “stock” (for ’61-64) location & run the complete CV drivetrain, including the driveshaft without alteration.

I did some measuring on the truck & find that (due to the previously discussed measurement issues) that the currently installed wheelbase on my truck is 114.5”. Wow. I’m there!

But then I think to my other reading. On the 65’s & up, the wheelbase is 115”, the inch gained by pushing the front axle forward - which means I’m currently halfway between “stock” for ‘61-‘64 & “stock” for ‘65 & up.

Most of the guys I’ve read about move the axle CL forward by ¾” to 1 ½” – on 65’s & up… that’s why the guys building the ’62 Unibody LSR pushed theirs forward 2 ½” – they went with the “normal” 1 ½” in front of the 65’s (& up) already 1” forward dimension.

I now realize that I was actually aiming for ¾” in front of the ‘65 & up measurement which means I now know I want 1 ¾” in front of 61-64 “stock” – or 1 ¼” further forward than I am right now. Are we having fun yet?

Now I knew the engine & transmission slid into position just fine with the CV suspension in place where it sits – but what would happen when I slid everything forward? Measuring the engine sitting on the floor, and then the frame, it sure looked like the AC compressor clutch would interfere with the front crossmember framerail brace. So I went ahead & dropped it in to be sure.

I’ve got about ¾” clearance as it sits. Moving the suspension (and the engine bolted to it) 1 ¼” forward puts me ½” into the brace. A half inch notch wouldn’t leave adequate space for movement & belt installation (who wants to pull the engine to replace the serpentine belt?) so I added another ¾” to give me a little bit of space for that. I marked out my cutlines & plan to use a section of scrap CV framerail (with its radius edge) to box the notch.

Now, moving the axle & engine forward gets the wheels where I want them in the wheel wells – but it also pulls my driveshaft 1 ¼” out of the transmission tailshaft housing. D’oh!

So now I’m thinking I’ll have to revisit my work on the rear suspension. Drilling the mono’s to move the axle forward doesn’t sound like the answer I’m willing to risk my own life upon, never mind those wife & (soon to be born) son. (No offense to the ’62 Unibody LSR guys – I’m building this to be a fun truck to drive, on the street, with stuff in the bed on occasion – I am a home builder after all – and I do like to turn corners quick & give her a little gas once in a while. I can’t even imagine what snapping a monoleaf would do on the road, in traffic.)

So I’m thinking of moving the forward leaf spring brackets 1 1/8”* forward on the frame, drilling new holes and attaching them with something other than grade 8 bolts**. Looking at the rear spring hangers, I think they’ll be fine where they are – they’ll just arc a little further forward. Or does anyone think that I should move them too?

Moving my rear axle centerline forward – has that got anyone else worried yet? I hate all the extra space in the fenders, so I want to section them 3” in the middle to tighten them up visually. This just means that instead of getting a donor step to cut slices out of to extend my steps (my former plan), I can just trim up my fenders. It’s always easier to make things smaller…

Now as to whether or not I can leave my existing C-notch alone… I’ll let you know. I guess if I need to revisit it, I’ll just have to do that!

Thoughts?

*Why 1 1/8 vs 1 ¼? The CV wheelbase is 114.6. I’m currently 114.5. The tenth is “close enough” to 1/8 for conversational purposes. And frankly, I’d rather hang the yoke .025 further out of the tailshaft housing than .1” too far in – I think in too deep could cause more problems, right?

**I read a huge metallurgical tirade on Fordification about what bolts should and shouldn’t be used to attach suspension pieces, and it convinced me that grade 8 isn’t the answer here – I’ll see if I can find the link.

Last edited by Rusty 63 on December 19, 2010, 4:40 am, edited 1 time in total.

Not sure drilling the Monos will be a big issue if you take your time and don't overheat the metal. If you keep it cool enough you won't damage the heat treating.

Move the spring hangers?

I'd take a long hard look at how that will affect the wheel/wheel arch in the rear though.

I'd probably have a beer - expel a few choice words and have the driveshaft lengthened.

Move the spring hangers?

I'd take a long hard look at how that will affect the wheel/wheel arch in the rear though.

I'd probably have a beer - expel a few choice words and have the driveshaft lengthened.

1964 F 100 - I am going to do "something" with it.......

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

Hey, if you guys think drilling the monos is safe - it'd sure be a heck of a lot quicker & easier too!

I've got the flare side bed - so the fenders are pretty straight in the mid-section (looking from the side, in profile). The hard part is that they actually get skinnier (looking from above) as you go towards the rear. Part of me wants to "fix" that as well...

I've got the flare side bed - so the fenders are pretty straight in the mid-section (looking from the side, in profile). The hard part is that they actually get skinnier (looking from above) as you go towards the rear. Part of me wants to "fix" that as well...

I wouldn't do it based just on what I said - just seems to make sense that if you don't affect the heat treating you'd be fine. Thought it was worth investigating - I'd call a big truck spring shop or even have them do it.

Moving the spring hangers wouldn't be that bad either since you have it all apart anyway.

Moving the spring hangers wouldn't be that bad either since you have it all apart anyway.

1964 F 100 - I am going to do "something" with it.......

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

Scroll back to page 1. The rear suspension is all together... all I need to do is set the CV's 8.8 onto some leaf spring perches & bolt it up.

I'm concerned about the rotational forces of acceleration & braking applied to an area not designed for it. Not to mention the extra hole could be a weak spot.

I'm concerned about the rotational forces of acceleration & braking applied to an area not designed for it. Not to mention the extra hole could be a weak spot.

I looked mine - I think you may be right plus I think the clamping forces on the pad will end up in a section that begins to taper.

Moving your spring perches will require a little repaint work back there but probably the best bet. It's a bit time consuming getting the old rivets out.

Or do the driveshaft.

Moving your spring perches will require a little repaint work back there but probably the best bet. It's a bit time consuming getting the old rivets out.

Or do the driveshaft.

1964 F 100 - I am going to do "something" with it.......

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

It isn't THAT bad to do. Takes some time, yes - but not that bad.

1964 F 100 - I am going to do "something" with it.......

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

So I’m thinking of moving the forward leaf spring brackets 1 1/8”* forward on the frame, drilling new holes and attaching them with something other than grade 8 bolts**. Looking at the rear spring hangers, I think they’ll be fine where they are – they’ll just arc a little further forward. Or does anyone think that I should move them too?

This is what I would vote for. Drilling the new holes in the frame is not that bad. Grade 8 bolts will be fine. I wouldn't bother with the back hangers.

I rechecked the other site. I was confused - the guy was saying grade 8 is good for suspension, not for frame crossmembers...

The bolt holes should be a lot easier than the overhead hole-saw holes I'm dealing with up front.

Looks like I'm ready to get back into it. Updated my autocad drawings/templates (they're not really necessary, but I like to fine tune dimensions onscreen with 1/16th accuracy, rather than rely upon hand-drawn lines on wood...

Now I just need some garage time!

The bolt holes should be a lot easier than the overhead hole-saw holes I'm dealing with up front.

Looks like I'm ready to get back into it. Updated my autocad drawings/templates (they're not really necessary, but I like to fine tune dimensions onscreen with 1/16th accuracy, rather than rely upon hand-drawn lines on wood...

Now I just need some garage time!

jwh f-100 wrote:Personally I wouldn't even consider drilling the springs or moving hangers. Leave it as is and have a driveshaft made..

BTW, looks great. I want to do something similar on my next project..

Moving the hangers is to get the axle where he wants it in the wheel well...it also happens to solve his driveshaft issue.

Braces

I have been thinking about the angled brace you are going to cut for AC compressor clearnace. You may want to consider removing the angled brace on both sides. The front crossmember is not needed as much with the new CV crossmember. A twin I beam truck does not have any crossmember in front of the one under the engine.

Re: Braces

bluebolt wrote:I have been thinking about the angled brace you are going to cut for AC compressor clearnace. You may want to consider removing the angled brace on both sides. The front crossmember is not needed as much with the new CV crossmember. A twin I beam truck does not have any crossmember in front of the one under the engine.

True, but the twin I trucks are welded and riveted in. The CV is just 4 bolts.

I would NOT remove that 45* frame brace unless you replace it with another heavy gusset in the corners. Done right you could get rid of them and keep the rigidity.

Not a thing wrong with what you have in mind IMHO.

Not a thing wrong with what you have in mind IMHO.

1964 F 100 - I am going to do "something" with it.......

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.

viewtopic.php?f=32&t=15942

1987 Mustang LX Convertible, 2.3 Auto - cruiser.

1994 F 150 XLT 2WD

~ Yes - I adopted another cat..............

Cam L Milan,

You'll be missed my friend.